Well at long last we have some 8x58RD Dies, they are new, robust and of unknown maker however they are dies and that is a good start as far as I am concerned so the next thing is get some rounds built.

I had planned on taking standard Berdan primed brass and either converting it to boxer or just reloading them as Berdan. The only downside with Berdan primed brass is removing the primers and that is no real hardship as they are easily removed hydraulically or you can always mess around with other techniques if so desired. Hydraulic removal of primers is a wonderful process, find a lump of wood and drill a shallow hole to match the diameter of the cartridge head or rim, now drill a smaller hole to allow the primer to drop through. Now fill the case 3/4 full with water place it in the hole in the wood, find a suitable piston which in this case is a length of brass that fits fairly snugly through the top of the case, insert the piston, hold it firmly (Gloves are good if it is a bit on the short side) now give it a smart rap with something and voila, the primer is pushed out with the hydraulic action, you get a bit wet and the case is ready to be cleaned and sized before priming. You will need the correctly sized primers however that is not a real problem. I much prefer to do this outside on a sunny afternoon and find it quite therapeutic…

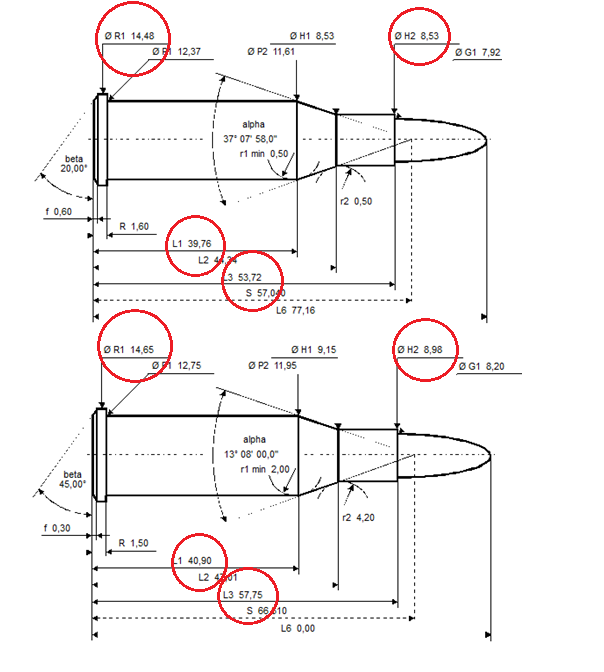

The problem is I do not have any fired 8x58RD brass right now so what are the alternatives? Well there is some new Bertram brass available however it has a reputation for splitting even when annealed and it is very expensive. Certainly other cases such as the 45/90 can be necked down however this involves trimming and annealing and again the brass is not cheap. There is a third option and that is to use 7,62x54R brass which is something we have a fair few of here having shot various Russian rifles in the past. Now one of the issues with 54R brass is it is going to come up short once it has been opened up to suit the 8,0mm however it does have a reputation for working fairly successfully and also means as I am reloading I can keep the MV’s down to something sensible.

Now to the choice of bullet, standard jacketed bullets of around 200 grains would be a good start however given that the two rifles have less than perfect bores I am inclined to use cast bullets which means I need to slug the bore first to confirm the best choice of bullet. Slugging is the process of taking an oversize to the bore lead slug or ball and forcing it down the bore, this does sound rather harsh however it is surprisingly easy. Lubricate the bore with some oil, take the slug and tap it down into the bore from the muzzle end and once it is in the bore it will tap down with very little effort, I prefer to use lengths of oak dowel however others will use a single length of suitable round bar, I found this method less easy as the rod will bow during the process if you are not careful plus if you are working with a 30″ barrel you end up having to stand on a chair to start the process. The lengths of oak dowel have worked perfectly many times in the past and I will continue to use them.

Once the slug drops out of the other end it can be measured and used as an indication of the diameter bullet to be used. Of course at this stage it is worth taking a cast of the chamber as well so you have a better idea of what you are working with but I am not going to pursue that avenue in this post as accurising cartridges for cast bullets is a whole subject on it’s own and way beyond this article.

I guess the next job is to decide on what sort of powder load to go for. A serious consideration is the maximum safe pressure for the rifles in question is going to be around 3200 Bar/46,500 PSI – CAUTION!! This applies to the later 8x58RD such as the S&L M.38/M.42 and not to the earlier rolling block One thing I do not want to do is overly stress the rifle so I suspect I will be looking at a fairly modest load of N140 or similar. Time to do some more research in this area meanwhile I will machine a mandrel, open up some 54R brass and see how it looks.