I will assume you have suitable tools for the job and in addition wear some safety glasses just in case you decide to follow my notes be warned, these are my notes for my rifle and I may have missed or not recorded something critical so if in doubt ask a grown up 🙂

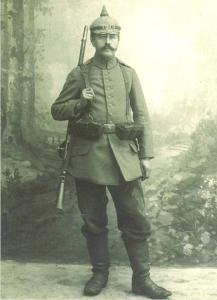

As I have mentioned already I now have a Gewehr 88/05 here and decided to take some time out this afternoon to take a closer look at what I have, dismantle, clean and inspect the rifle thoroughly and make some notes. I am a great believer in looking with my hands and thoroughly cleaning everything as this is the time when any potential issues will be spotted.

Removing the barrelled action from the stock: All you should need at this stage are a couple of flat bladed screwdrivers and some patience. Do remember when stripping a Gewehr88 that these are 120+ year old service rifles so use the correct fitting tools and take your time and if something is tight or not immediately obvious stop and research the problem. The rifle has lasted this long and you should consider yourself the custodian not the owner, accordingly just think of it as if you were working on someone else’s rifle.

First job, make sure the rifle is safe and remove the bolt.

Unscrew the cleaning rod and remove it then unscrew the front band retaining screw and push the front end off the stock. It may be tight so use a drift if needed, I have an assortment of brass and steel drifts and punches that I use and I supplement these with hard wood drifts. I make all of my own tools of this type however you can always buy a brass punch set and cut a piece of hard wood or even a piece of hard nylon to size to act as a drift for things like barrel bands.

With the front band removed, depress the catch in front of the rear band and slide it forward taking care not to scuff the stock.

Now slacken and remove the two trigger guard/magazine screws and rock the barrelled action from the stock, take your time as it is easy to chip the stock at this stage.

You should now have a barrelled action separate to the stock, keep things tidy by placing the screws and bands in a suitable container, the long screw goes at the back.

Next job is remove the barrel sleeve by unscrewing it from the front of the receiver, once unscrewed slide it out of position and place it somewhere safe, you should now have something that looks a bit like this.

Next job is remove the barrel sleeve by unscrewing it from the front of the receiver, once unscrewed slide it out of position and place it somewhere safe, you should now have something that looks a bit like this.

I spent a while thoroughly cleaning everything at this stage of progress and making a note of any markings and potential defects as I went along. A camera is always handy when stripping a firearm you are not familiar with. These days even a mobile ‘phone camera will suffice if you have such a thing. I do indeed have a mobile ‘phone however as normal it was somewhere else, luckily the Viking’s camera was to hand and hopefully she will not notice any grubby fingermarks I may have left on it…

A word on cleaning, I use a variety of processes and materials for cleaning a rifle, a wash tank, lighter fluid and acetone all have their place. A dishwasher is also superb for cleaning larger parts once you have removed the worst of the oil and grease. I will also happily place rifle stocks in a dishwasher if I am going to re-finish them and they will fit, this is also a handy way of raising smaller dents however there is a technique to this and I really do urge you to experiment before stuffing your favourite rifle in a dishwasher once dismantled as you may be in for a bit of a shock.

I also use copious amounts of kitchen roll and old rag such as torn up T Shirts, finally these days I am experimenting with something called ‘Wonder Wipes’ however I am not fully convinced by them when it comes to cleaning old service rifles.

OK, so the rifle is clean now, what next? Well the first picture should give you an idea of the general state of the rifle so first job was the trigger guard.

Stripping the magazine and trigger guard process: Remove the lower dust cover if fitted, then depress the spring loaded cartridge follower and the plunger will appear from the rear of the guard, place a suitably sized pin through the hole in it to hold it away from the cartridge follower.

Unscrew and remove the three screws in the guard body.

Drift out the main block from the upper side with a soft drift.

Drift out the rear block with a soft drift, this should be drifted back and down as it has two angled tabs holding it in place.

Lift the cartridge follower out from the underside.

Use a flat bladed screwdriver as a lever top compress the spring and plunger, remove the pin and decompress – take care as it may have a tendency to fly out if it slips.

Reassembling the magazine and trigger guard assembly: This is the reverse procedure of above however here are my notes on the process:

Insert the cartridge follower plunger and spring from the underneath this is easily levered in place with a flat bladed screw driver until the back end of the plunger appears. You will note there is a convenient hole in the rear of the plunger as it emerges and you can pop a pin or small screw driver in here to hold it in place.

Next insert the cartridge follower from the underneath and hold in place with one of the three screws, you can now depress the cartridge follower against the spring plunger and remove the screw driver or pin used to hold it out and it is now re assembled.

Next insert the cartridge follower from the underneath and hold in place with one of the three screws, you can now depress the cartridge follower against the spring plunger and remove the screw driver or pin used to hold it out and it is now re assembled.

Replace the bottom rear plate, make sure the two tangs are correctly aligned and then carefully tap the plate forwards and down towards the rear with a soft nosed drift until fully in place and secure with a screw.

Finally replace the upper by locating and tapping in place and secure with your remaining screw. Run a function check.

Receiver: The cartridge/case keeper on the G88/05 is held in place by a screw and spring on the left hand side of the receiver, to remove the guide undo the screw, remove the spring, you can now push the guide out with your fingers from the inside of the receiver.

Reverse this procedure to replace, you will notice that the cartridge guide is handed and can only go back in one orientation, the flat spring has a small round section on the opposite end to the screw hole, this engages into the hole on the cartridge guide to lock it in place. Once replaced you should be able to spring the guide in and out with your fingers to confirm operation.

Removing the trigger: Remove the trigger retaining pin that connects the assembly to the receiver with a suitable drift, and remove, taking care not to lose the trigger spring. The trigger can be further dissembled if required however unless you are experiencing specific problems with the trigger and are comfortable with working on such things it is probably best left alone.

It is worth inspecting the sear at this stage while everything is apart to make sure it is not damaged.

Trigger reassembly: Once you have cleaned and inspected the trigger and satisfied yourself that it is ready to be reassembled to the receiver place the trigger spring into the hole and slide the trigger assembly into place whilst compressing the spring. I used a flat bladed screw driver and my thumb to get everything in place and pushed a temporary over length pin in place between the trigger and the trigger hanger.

Once happy with everything tap the original keeper pin back in place, doing it this way ensures everything is correctly aligned. A word of warning, the trigger spring is yet another item that might make a bid for escape so beware.

Check operation of the trigger yet again.

Bolt assembly To reassemble the bolt insert the firing pin into the bolt head, you need to make sure this is correctly orientated which is the lug of the bolt head should be on the same  side as the single flat to the rear of the firing pin just before the diameter reduces to the threaded section.

side as the single flat to the rear of the firing pin just before the diameter reduces to the threaded section.

Slide the spring into place over the firing pin ready for assembly, this is my way of doing things however something different might work for you.

I stand the firing pin and bolt head upright and take the bolt in my right hand

with the bolt handle in the palm of my hand, I then push it down over the firing pin assembly and hold it in place under tension. Then locate the rear section of the bolt in place and rotate the whole bolt assembly around the bolt head by a few degrees in an anti clock wise to lock everything in place and stops it from flying apart.

Take care as the firing pin spring is now under compression; if slightly rotated back the whole assembly can fly apart.

Now locate the safety flag and spring into location, you can now screw the cocking piece onto the rear threaded section once you have a few turns on the cocking piece it is safe to let go, the cocking piece should be tightened fully.

Insert the bolt into the receiver and perform a full function test of the action, trigger and safety.

Bolt Safety positions:

Safety catch to left, rifle can be fired.

Safety catch to right, rifle is safe and cannot be fired.

Rifle reassembly: At this stage you should have some nice clean and lightly oiled where necessary sub assemblies ready to go back together. My barrel was in the white and I am going to replace it however I also lightly oiled the barrel before fitting the barrel shroud, I had cleaned the stock internals however I left the external surface virtually as found to maintain the patina of age.

Place the barrelled action into the stock and turn the rifle over, locate the trigger guard in place and secure with the two screws, long at the back, you do not need to tighten these two screws excessively, just nip them up reasonably tight. I usually make a note of the position of the screw slots before stripping so they can be returned to the same position, it sounds odd however screw tension can really upset accuracy on an older rifle and you can always fine tune tension when you get down the range.

Next slide the rear barrel band into place, any stamps or markings are probably going to be on the left hand side, now slide the front barrel band into place and secure with the screw you put somewhere safe a couple of hours ago, finally screw the cleaning rod back in place and fit the bolt.

You have just completely stripped and reassembled a rifle so run a full function check for bolt release, trigger and safety operation and finally dry fire it a few times to really satisfy all is good.